- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- 30 MT Welding Positioner

- WM-5000 Welding Positioners

- WM-1000 Welding Positioner

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Rotary Welding Positioner

- Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Motorised Lead Screw Welding Rotator

- Variable Speed Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Self Aligning Welding Rotators

- Lead Screw Type Welding Rotator

- 25 Tone Capacity Welding Rotator

- Motorised Trolley Type Welding Rotator

- High Capacity Welding Rotators

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

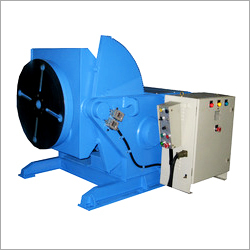

Low Duty Welding Positioner

201000 INR/Set

Product Details:

- Automation Grade Semi-Automatic

- Application Pipe, Flange, Plate Welding

- Current Range 10 A - 160 A

- Equipment Type Welding Positioner

- Output Voltage 24V

- Diameter 350 mm

- Power Source Electric

- Click to View more

X

Low Duty Welding Positioner Price And Quantity

- 1 Set

- 201000 INR/Set

Low Duty Welding Positioner Product Specifications

- AC Motor

- 0.75 kW

- Semi-Automatic

- Mild Steel

- 220V AC

- Electric

- 100 kg

- Low Duty

- 24V

- Suitable for MIG, TIG, and Arc Welding

- Single Phase

- 350 mm

- 220V

- 10 A - 160 A

- Pipe, Flange, Plate Welding

- 0.75 kW/h

- Welding Positioner

- 1.5 A

- 50 Hz

- New

- 500 mm x 400 mm x 350 mm

Low Duty Welding Positioner Trade Information

- 20 Set Per Month

- 4-6 Week

- Wooden Packaging

- All India

Product Description

We have established ourselves as the top manufacturer, supplier and exporter engaged in offering an innovative collection of Low Duty Welding Positioners. Our provided welding positioner is manufactured with advanced technology and top quality material in accordance with quality norms. These Low Duty Welding Positioners find special usage in meeting the welding application demands of barrels where these provide functionality as a kind of deflection machine with functions of upset as well as gyration that can put the weld surface into best position.

Features:

- Heavy duty design

- Smooth functioning

- Require less maintenance

- Noise less performance

Enhanced Welding Productivity

By enabling controlled rotation and tilting, the welding positioner reduces repositioning time and increases accessibility to hard-to-reach weld seams. The variable speed feature supports precise adjustments for different welding techniques, resulting in improved weld quality and reduced operator fatigue. Semi-automatic control streamlines repetitive processes, making it an invaluable tool for small-scale fabrication and repair.

Versatile Applications and Mounting

This welding positioner is floor-mounted and suited for use in workshops, manufacturing units, and repair facilities. It is especially effective when working on pipes, flanges, and plates, thanks to its customizable chuck options and adjustable surface plate. The robust mild steel construction ensures stable performance even with frequent load changes, making it ideal for low duty industrial requirements.