- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- 30 MT Welding Positioner

- WM-1000 Welding Positioner

- WM-5000 Welding Positioners

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Welding Positioner

- Rotary Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Motorised Lead Screw Welding Rotator

- Variable Speed Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Self Aligning Welding Rotators

- Lead Screw Type Welding Rotator

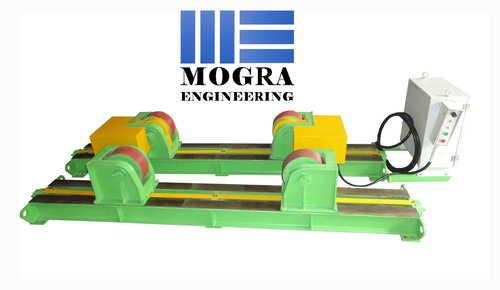

- 25 Tone Capacity Welding Rotator

- Motorised Trolley Type Welding Rotator

- High Capacity Welding Rotators

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- MOGRA 5MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

25 Tone Capacity Welding Rotator

436000 INR/Set

Product Details:

- Welding Submerged Arc/Manual/Automatic

- Current Range 50 600 A

- Application Tank/Vessel Fabrication, Pipe Welding

- Diameter 300 5000 mm

- Power Source Electric

- Output Voltage Adjustable

- Phase 3 Phase

- Click to View more

X

25 Tone Capacity Welding Rotator Price And Quantity

- 436000 INR/Set

- 1 Set

- 25 Ton/Drive + Idler pairing

- 400 mm

- -10C to +45C

- Cylindrical Workpieces

- IP54

- 200 mm

- 100 2000 mm/min (Variable Frequency Drive)

- Floor Mount

- Remote Push Button Pendent

- PU/Steel

- Powder Coated / Painted

25 Tone Capacity Welding Rotator Product Specifications

- 300 5000 mm

- 50/60 Hz

- Mild Steel

- 415V AC

- Electric

- AC Motor

- Welding Rotator

- Low / Efficient

- 3 kW

- 50 600 A

- Self-Aligning Welding Rotator

- New

- Tank/Vessel Fabrication, Pipe Welding

- 12A

- Semi-Automatic

- 415 V

- Submerged Arc/Manual/Automatic

- Customized / Standard

- 25 Tons

- 3 Phase

- Adjustable

- 25 Ton/Drive + Idler pairing

- 400 mm

- -10C to +45C

- Cylindrical Workpieces

- IP54

- 200 mm

- 100 2000 mm/min (Variable Frequency Drive)

- Floor Mount

- Remote Push Button Pendent

- PU/Steel

- Powder Coated / Painted

25 Tone Capacity Welding Rotator Trade Information

- 12 Set Per Month

- 4-5 Week

Product Description

As the leading manufacturer, supplier and exporter, we are presenting a wide range of Industrial Lead Screw Welding Rotators. Our provided welding rotator is manufactured with advanced technology and top quality material in accordance with quality norms. The machine consists of INo Drive unit and INo Idler unit and Control panel with pendant. The offered Industrial Lead Screw Welding Rotators are used to rotate or position the cylindrical jobs for circumferential welding (TIG / MIG / Sub Arc) or for intricate assemblies.

Specification

| Capacity | 20 Ton |

| Phase | Three Phase |

| Frequency | 50/60 Hz |

| Voltage | 400-415 V |

| Brand | Mogra |

Features:

- High efficiency

- Smooth performance

- Low maintenance cost

- Rigid design

High-Capacity Performance

Constructed with drive and idler pairing, this welding rotator supports up to 25 tons, ensuring reliable rotation even for large vessels or tanks. Its variable frequency drive facilitates precise speed control necessary for different welding applications.

Versatile Applications

Designed for cylindrical workpieces, the equipment excels in pipe welding, tank fabrication, and vessel manufacturing. Suitable for manual, automatic, and submerged arc welding processes, it addresses a wide spectrum of industry demands.

Enhanced Control and Safety

With remote push-button pendant controls, operators experience ease of use and enhanced safety. The IP54 protection class, powder coating, and painted surfaces defend against dust and moisture, ensuring consistent performance in industrial settings.

FAQs of 25 Tone Capacity Welding Rotator:

Q: How does the 25 ton welding rotator accommodate various workpiece diameters?

A: This welding rotator is self-aligning and equipped with PU/steel rollers, allowing it to handle cylindrical workpieces with diameters ranging from 300 to 5000 mm, ensuring stable rotation and precise welding for different sizes.Q: What type of control system is provided with the welding rotator?

A: The equipment features a remote push button pendant control system, enabling users to operate the rotator from a safe distance, improving workflow flexibility and worker safety during tank, vessel, or pipe manufacturing.Q: When is it recommended to use a welding rotator with variable frequency drive?

A: A variable frequency drive is ideal when consistent and adjustable rotation speeds are necessary, such as in submerged arc, manual, or automatic welding processes. It allows operators to set the speed (1002000 mm/min) for optimum fabricating quality.Q: Where should this welding rotator be installed for best results?

A: The machine is designed for floor mounting, providing stability and sturdy support for heavy workpieces. Its best situatated in industrial workshops, fabrication plants, or manufacturing facilities specializing in tanks, vessels, and pipework.Q: What process benefits does the powder-coated/painted surface offer?

A: A powder-coated or painted surface ensures improved durability, corrosion resistance, and longevity, especially when operating within the ambient temperature range of -10C to +45C and under industrial conditions.Q: How does the IP54 protection class enhance equipment reliability?

A: IP54 rating safeguards the welding rotator against dust ingress and water splashes, making it suitable for challenging industrial environments and ensuring dependable operation and minimal maintenance requirements.Q: What are the primary usage and benefits of using this semi-automatic welding rotator?

A: The semi-automatic rotator streamlines welding processes for large cylindrical objects, reducing manual intervention. This results in improved weld quality, higher productivity, reduced labor costs, and safer operations during tank and pipe fabrication.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email