- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- WM-1000 Welding Positioner

- 30 MT Welding Positioner

- WM-5000 Welding Positioners

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Welding Positioner

- Rotary Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Motorised Lead Screw Welding Rotator

- Variable Speed Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Self Aligning Welding Rotators

- Lead Screw Type Welding Rotator

- 25 Tone Capacity Welding Rotator

- Motorised Trolley Type Welding Rotator

- High Capacity Welding Rotators

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

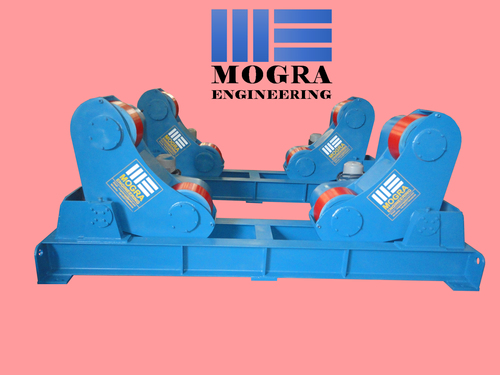

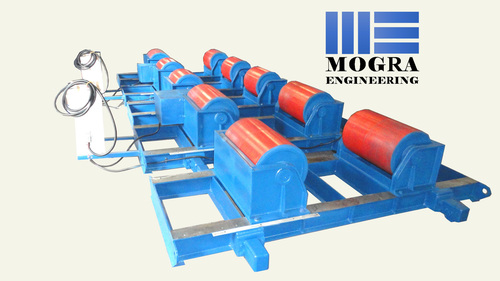

Welding Rotator 2 Ton Capacity

125000 INR/Set

Product Details:

- Automation Grade Semi-Automatic

- Frequency 50 Hz

- Welding Rotator for Pipe & Tank Welding

- Power Source Electric

- Phase 3 Phase

- Application For rotating cylindrical workpieces during welding

- Diameter 50 mm - 2000 mm

- Click to View more

X

Welding Rotator 2 Ton Capacity Price And Quantity

- 125000 INR/Set

- 1 Set

- IP54

- Powder Coated

- 3000 mm

- Polyurethane-coated Steel

- <75 dB

- Variable (Adjustable)

- Single Motor Drive

- 100-1000 mm/min

- PU (Polyurethane) Wheels

- Circular, Pipe, Tank Welding Applications

- 2 Ton

- Remote Pendant Control

Welding Rotator 2 Ton Capacity Product Specifications

- 1200 x 650 x 500 mm

- 3 Phase

- For rotating cylindrical workpieces during welding

- 50 mm - 2000 mm

- Mild Steel

- 415 V AC

- Low

- Pipe and Tank Welding Rotator

- Semi-Automatic

- 2 Ton

- Welding Rotator

- 415 V

- 50 Hz

- 3.5 A

- 1.5 kW

- New

- Electric

- Electric

- Rotator for Pipe & Tank Welding

- IP54

- Powder Coated

- 3000 mm

- Polyurethane-coated Steel

- <75 dB

- Variable (Adjustable)

- Single Motor Drive

- 100-1000 mm/min

- PU (Polyurethane) Wheels

- Circular, Pipe, Tank Welding Applications

- 2 Ton

- Remote Pendant Control

Welding Rotator 2 Ton Capacity Trade Information

- 12 Set Per Month

- 4-5 Week

Product Description

Welding rotator lead screw type capacity- 2 tonne job diameter- 200 to 3000 mm customer- majees technologies oman

Specification

| Capacity | 2 Ton |

| Phase | Three Phase |

| Voltage | 400-440 V |

| Weight | 100-200 Kg |

| Frequency | 50 Hz |

| Output Current | 0-100 (A) |

| Warranty | 1 Year |

Precision and Flexibility for Pipe and Tank Welding

Engineered with adjustable roller center distances, the welding rotator offers flexibility to handle workpieces of varying diameters and lengths up to 3000 mm. Polyurethane-coated steel rollers ensure gentle yet secure movement, making it suitable for delicate surfaces while maintaining a firm grip for seamless rotation.

Advanced Remote Control Operation

The rotators remote pendant control allows operators to adjust rotation speed from 100 to 1000 mm/min with ease, optimizing welding procedures for different material types and thicknesses. Its single motor drive and semi-automatic mode promote smooth operation, reducing manual intervention and enhancing process safety.

Durability and Safety Features

Constructed with mild steel and powder coating, the equipment boasts durability and corrosion resistance. With an IP54 protection degree, it is safeguarded against dust and moisture, guaranteeing longevity even in challenging industrial environments. The noise level stays under 75 dB, supporting a comfortable workspace.