- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- WM-1000 Welding Positioner

- 30 MT Welding Positioner

- WM-5000 Welding Positioners

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Rotary Welding Positioner

- Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Variable Speed Welding Rotator

- Motorised Lead Screw Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Lead Screw Type Welding Rotator

- Self Aligning Welding Rotators

- 25 Tone Capacity Welding Rotator

- Motorised Trolley Type Welding Rotator

- High Capacity Welding Rotators

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- MOGRA 5MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

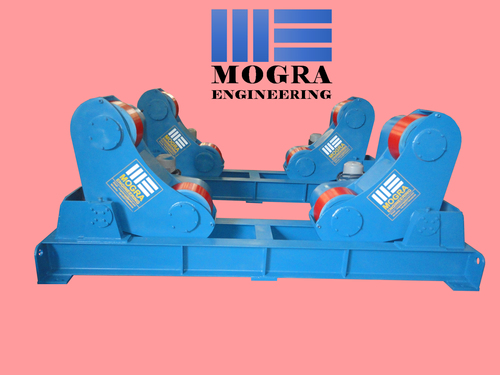

Lead Screw Type Welding Rotator

590000 INR/Set

Product Details:

- Welding Positioning/Rotating for Automated Welding

- Diameter Range up to 4500 mm

- Application Pipe, Vessel, and Tank Welding Rotation

- Frequency 50 Hz

- Phase Three Phase

- Current Range 10-200 A (Machine-operated)

- Automation Grade Semi-Automatic / Automatic

- Click to View more

X

Lead Screw Type Welding Rotator Price And Quantity

- 590000 INR/Set

- 1 Set

Lead Screw Type Welding Rotator Product Specifications

- Customizable as per requirement

- Lead Screw Type Welding Rotator

- Low Power Consumption

- Mild Steel

- 380 V

- Positioning/Rotating for Automated Welding

- Semi-Automatic / Automatic

- 4 kW

- AC Motor

- 380 V

- Welding Rotator

- Range up to 4500 mm

- Pipe, Vessel, and Tank Welding Rotation

- 10-200 A (Machine-operated)

- New

- Three Phase

- Electric

- 5 Tons / 10 Tons / 20 Tons (Model Dependent)

- 50 Hz

- 10 A

- Variable (Controllable Speed)

Lead Screw Type Welding Rotator Trade Information

- 12 Set Per Month

- 4-5 Week

Product Description

WELDING ROTATOR

LEAD SCREW TYPE

CAPACITY- 10 TON

JOB DIAMTER- 400 TO 4000

CUSTOMER- FINN MARINE ( INDONESIA)

Specification

| Capacity | 300 Ton |

| Phase | Three Phase |

| Power Source | Electric |

| Voltage | 400-440 V |

| Frequency | 50 Hz |

| Output Current | 0-100 (A) |

Adaptable to Varied Workpieces

The Lead Screw Type Welding Rotator offers customizable dimensions and roller optionspolyurethane or steelensuring compatibility with a wide diameter range (up to 4500 mm) and various vessel weights up to 20,000 kg. Its modular design accommodates heavy-duty industrial applications, making it suitable for fabricators who manage diverse welding projects.

Precision Operation with Enhanced Control

Integrated with a digital control panel or remote pendant, this rotator grants precise control over rotating speed, ranging from 100 to 1000 mm/min. Whether used in semi-automatic or fully automated workflows, the system guarantees consistent rotation for optimal weld seam quality, while features like overload protection and emergency stop promote operator safety.

Efficient and Safe for Industrial Environments

Powder coated or painted for lasting protection, the rotator is constructed from mild steel and powered by an efficient 4 kW AC motor. Its low power consumption, three-phase compatibility, and minimal noise generation make it ideal for continuous, high-volume operation in heavy-duty settings, ensuring reduced downtime and increased productivity.

FAQs of Lead Screw Type Welding Rotator:

Q: How does the lead screw adjustment improve roller positioning in this welding rotator?

A: The lead screw adjustment provides manual, precise alignment of the rollers to securely accommodate workpieces with different diameters. This ensures stable rotation and optimal positioning of pipes, vessels, or tanks during welding, reducing setup time and potential misalignment issues.Q: What are the available roller materials, and when should polyurethane or steel rollers be selected?

A: Our rotator offers polyurethane and steel roller materials. Polyurethane rollers are ideal for delicate surfaces or non-marring applications, while steel rollers are recommended for heavy-duty tasks involving high temperatures or abrasive contact, such as steel vessel fabrication.Q: Where can this welding rotator be used most effectively?

A: This equipment is best suited for industrial and heavy-duty environments, including fabrication shops and manufacturing facilities that require precise, safe rotation of pipes, tanks, or vessels during automated or semi-automatic welding processes.Q: What control options are available for operating the rotator?

A: The rotator can be operated via a remote pendant control or a digital control panel. Both options offer variable speed management, ensuring convenient and precise control over the rotation during welding.Q: How does the safety system function, and what benefits does it offer?

A: The rotator is equipped with overload protection and emergency stop features. These mechanisms prevent equipment damage and enhance operator safety by instantly halting operation when required, providing peace of mind in industrial settings.Q: What is the process for extending the system to accommodate longer or heavier vessels?

A: You can pair the drive rotator with idler rotators, which support and stabilize extended or heavy workpieces. This modular approach increases capacity and versatility, making it easier to handle complex welding projects.Q: What advantages does this welding rotator provide for automated welding applications?

A: It ensures consistently smooth rotation for improved weld seam quality, lowers manual handling risks, and boosts productivity with low noise and power consumption. Its customizable features and robust construction make it a valuable addition to automated welding workflows.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email