- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- 30 MT Welding Positioner

- WM-1000 Welding Positioner

- WM-5000 Welding Positioners

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Rotary Welding Positioner

- Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Motorised Lead Screw Welding Rotator

- Variable Speed Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Self Aligning Welding Rotators

- Lead Screw Type Welding Rotator

- 25 Tone Capacity Welding Rotator

- Motorised Trolley Type Welding Rotator

- High Capacity Welding Rotators

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

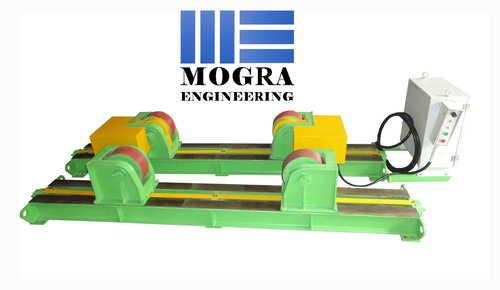

Self Aligning Welding Rotators

1605000 INR/Set

Product Details:

- Power Consumption Standard as per model - energy efficient

- Power Source Electric

- Frequency 50/60 Hz

- Welding Suitable for SAW/MIG/MAG/TIG processes

- Diameter Suitable for tank diameter 300mm - 5000mm (varies by model)

- Output Voltage As per motor (typically 24V control transformer for panel)

- Current Range Standard 60A to 300A (custom options)

- Click to View more

X

Self Aligning Welding Rotators Price And Quantity

- 1 Set

- 1605000 INR/Set

- Industrial – Fabrication shops, Pressure vessel works, Pipe manufacturing plants

- Floor mounted, bolt-on rails as option

- Standard: 300mm; customizations available

- Remote pendant with forward/reverse and variable speed

- Powder Coated / Painted

- Dual drive with AC variable frequency drive

- Overload protection, Safety interlocks

- Low noise operation (<70 dB)

- 5 to 200 tons

- Available for special tank sizes and capacities

- Rubber / PU / Steel

- 100 to 1000 mm/min (variable speed)

Self Aligning Welding Rotators Product Specifications

- As per motor (typically 24V control transformer for panel)

- Standard as per model - energy efficient

- Standard 60A to 300A (custom options)

- 4 kW (Standard models, customizable)

- Customizable as per capacity model

- Electric

- Automatic / Semi-automatic

- New

- AC Electric Motor

- Mild Steel, Rubber Roller

- 380V / 415V (standard)

- 50/60 Hz

- 5 Ton to 200 Ton (as per model)

- Self Aligning Welding Rotator

- Suitable for SAW/MIG/MAG/TIG processes

- Welding Rotator

- up to 10A

- 380V / 415V

- Suitable for tank diameter 300mm - 5000mm (varies by model)

- Three Phase

- Cylindrical workpiece rotation for welding, assembly, painting

- Industrial – Fabrication shops, Pressure vessel works, Pipe manufacturing plants

- Floor mounted, bolt-on rails as option

- Standard: 300mm; customizations available

- Remote pendant with forward/reverse and variable speed

- Powder Coated / Painted

- Dual drive with AC variable frequency drive

- Overload protection, Safety interlocks

- Low noise operation (<70 dB)

- 5 to 200 tons

- Available for special tank sizes and capacities

- Rubber / PU / Steel

- 100 to 1000 mm/min (variable speed)

Self Aligning Welding Rotators Trade Information

- 12 Set Per Month

- 4-5 Week

Product Description

As an eminent manufacturer, supplier and exporter, we bring forth our esteemed clients with a broad collection of Heavy Self Aligning Type Welding Rotators. As per the set quality norms, the offered welding rotator is designed by our professionals by utilizing the finest quality material and advanced technology. All models of Heavy Self Aligning Type Welding Rotators consist of a drive unit and an idler unit. In the drive section, rollers are motorized and regulated by a control panel. Moreover, we offer this welding rotator in numerous specifications within given time frames.

Specification

| Capacity | 120 Ton |

| Current | 0-100 A |

| Phase | Three Phase |

| Power Source | Electric |

| Frequency | 50/60 Hz |

| Usage/Application | Industrial |

| Voltage | 400-440 V |

Features:

- Easy to operate

- Optimum performance

- Long functional life

- Ensured better welding

Versatile Load Handling

With a robust load capacity spanning from 5 to 200 tons, these welding rotators are ideal for handling tanks and pipes of varying sizes in fabrication shops, pressure vessel works, and pipe manufacturing plants. Their adaptable design ensures reliable performance, even with custom tank specifications.

Advanced Control and Safety

Equipped with a remote pendant control system featuring forward/reverse and variable speed options, operators can manage rotation speeds from 100 to 1000 mm/min. The built-in safety features, including overload protection and safety interlocks, enhance operator confidence and reduce risks during industrial operations.

Customization and Efficient Operation

The rotators offer customizable roller diameters, surface finishings, and motor specifications, catering to unique project needs. Their energy-efficient AC electric motors and powder-coated or painted finishes provide durability and reduced maintenance, while low noise output ensures a comfortable working environment.