- Home Page

- Company Profile

- More About

-

Our Products

- Welding Positioners

- 30 MT Welding Positioner

- WM-5000 Welding Positioners

- WM-1000 Welding Positioner

- 100 Kg Capacity Welding Positioner

- 2 Tone Capacity Welding Positioner

- 1 Ton Welding Positioner

- Low Duty Welding Positioner

- Rotary Welding Positioner

- Welding Positioner

- Industrial Welding Positioners

- MOGRA 5MT Welding Positioner

- MOGRA Welding Positioner

- MOGRA 10MT Welding Positioner

- Industrial Heavy MOGRA 1MT Welding Positioner

- MOGRA 7MT Welding Positioner

- Steel MOGRA Welding Positioner

- MOGRA 0.25MT Welding Positioner

- MOGRA 1MT Welding Positioner (Torch Stand)

- MOGRA 0.1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner (Torch Stand)

- MOGRA 1MT Welding Positioner

- MOGRA 0.5MT Welding Positioner

- Welding Rotators

- Variable Speed Welding Rotator

- Motorised Lead Screw Welding Rotator

- Welding Rotator 15 MT Self Aligning Type

- Self Aligning Welding Rotators

- Lead Screw Type Welding Rotator

- 25 Tone Capacity Welding Rotator

- High Capacity Welding Rotators

- Motorised Trolley Type Welding Rotator

- Welding Rotator

- 5 Ton Welding Rotator

- Self Aligning Type Rotator

- Heavy Duty Welding Rotator

- MANUAL TROLLEY TYPE ROTATOR

- Welding Rotator 2 Ton Capacity

- Industrial Welding Rotator

- Welding Rotator 60 Mt Capacity With Motorised Trolley

- Welding Rotator 40 Mt Capacity

- Self Centering Rotator

- Welding Columns Booms

- Fit Up Rolls

- Special Purpose Welding Setups

- Mogra 30MT Detachable Trolley

- MOGRA Motorized Trolley Welding Rotator

- MOGRA Power Trolley Welding Rotator

- Mogra Pipe Inside L Seam Welding Setup

- MOGRA Frog Design Welding Positioner

- MOGRA 360 Degree Cradle Type Welding Positioner

- MOGRA Head Stock Welding Manipulator

- MOGRA Bogie Frame Welding Manipulator

- MOGRA Wind Mill Welding Positioner

- Mogra Make Pipe To Elbow Welding Setup

- Mogra Railway Engine Under Frame Welding Manipulator

- MOGRA Propeller Shaft Welding Setup

- Mild Steel Welding Rotator

- Mogra 5MT Welding Rotator ( Lead Screw Type On Inclined Base)

- MOGRA Sand Blasting Welding Rotator

- Welding Rotators - Lead Screw

- Mogra 70MT Welding Rotator ( Lead Screw Type)

- Heavy MOGRA 10MT Welding Rotator (Lead Screw Type)

- Three Phase MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Positioner Rotator (Lead Screw Type)

- MOGRA 25MT Welding Rotator (Lead Screw Type)

- MOGRA 5MT Welding Rotator (Lead Screw Type)

- MOGRA 10MT Welding Rotator (Lead Screw Type)

- MOGRA Welding Rotator (Lead Screw Type)

- Mogra 150MT Welding Rotator (Lead Screw Type)

- MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 30MT Welding Rotator (Lead Screw Type)

- MS MOGRA 20MT Welding Rotator (Lead Screw Type)

- MOGRA 50MT Welding Rotator (Lead Screw Type)

- Industrial MOGRA 15MT Welding Rotator (Lead Screw Type)

- MOGRA 20MT Welding Rotator (Lead Screw Type)

- Machined Components

- Welding Rotators - Self Aligning

- Heavy Steel MOGRA Welding Rotator (Self-Aligning Type)

- Mogra Welding Rotator (Self- Aligning Type)

- Mogra 15MT Welding Rotator ( Self-aligning Type)

- MOGRA Welding Rotator (Self-Aligning Type)

- MOGRA 5MT Welding Rotator (Self-Aligning Type)

- MOGRA 150MT Welding Rotator (Self-Aligning Type)

- Mogra 300MT Welding Rotator (Self- Aligning Type)

- MOGRA 60MT Welding Rotator (Self-Aligning Type)

- Welding Rotators - Conventional

- MOGRA 40MT Welding Rotator (Conventional Type)

- MOGRA 10MT Welding Rotator (Conventional Type)

- MOGRA 80MT Welding Rotator (Conventional Type)

- MOGRA 3MT Welding Rotator (Conventional Type)

- MOGRA 5MT Welding Rotator (Conventional Type)

- Mild Steel MOGRA 5MT Welding Rotator (Conventional Type)

- MOGRA Welding Rotator (Conventional Type)

- MOGRA 1MT Welding Rotator (Conventional Type)

- MOGRA 2MT Welding Rotator (Conventional Type)

- MOGRA 20MT Welding Rotator (Conventional Type)

- MOGRA 25MT Welding Rotator (Conventional Type)

- Welding Column and Boom

- Mogra 4mx4m Welding Column And Boom ( Medium Duty)

- Heavy MS Welding Column And Boom

- MOGRA 6Mx6M Welding Column And Boom (Pedestal Type)

- MOGRA 6Mx4M Welding Column And Boom

- MOGRA 2.5Mx3M Welding Column And Boom (Pedestal Type)

- Mogra Welding Column And Boom (Light Duty)

- Mogra Welding Column And Boom (Medium Duty)

- MOGRA 3Mx3M Welding Column And Boom (Pedestal Type)

- MOGRA 4Mx6M Welding Column And Boom

- Mogra 1mx1m Welding Column And Boom ( Light Duty)

- Welding Positioners

- Our Customers

- Contact Us

Welding Rotator

1350000 INR/Set

Product Details:

- Power Consumption 3.0 KW

- Power Source Electric

- Automation Grade Semi Automatic

- Current Range 50A - 1000A

- Equipment Type Pipe & Vessel Welding Rotator

- Phase 3 Phase

- Frequency 50 Hz

- Click to View more

X

Welding Rotator Price And Quantity

- 1 Set

- 1350000 INR/Set

- Variable

- 1000 mm

- 4

- 10000 kg

- < 70 dB

- IP54

- Powder Coated

- Polyurethane & Steel

- Blue & Yellow

- Remote Pendant & Foot Pedal

- Floor Mounted

- 100 - 1000 mm/min

Welding Rotator Product Specifications

- 50 Hz

- Mild Steel

- AC Motor

- 3 Phase

- 380V

- Welding Rotator

- 2 x 1.5 kW

- 3500 x 1000 x 950 mm

- Pipe & Vessel Welding Rotator

- 50A - 1000A

- 15-50V

- Electric

- 380V

- Pipe, Tank, Vessel & Cylinder Rotating

- New

- 8A

- Semi Automatic

- 10 Tons

- Submerged Arc / MIG / TIG / Manual

- 250 mm - 3500 mm

- 3.0 KW

- Variable

- 1000 mm

- 4

- 10000 kg

- < 70 dB

- IP54

- Powder Coated

- Polyurethane & Steel

- Blue & Yellow

- Remote Pendant & Foot Pedal

- Floor Mounted

- 100 - 1000 mm/min

Welding Rotator Trade Information

- 12 Set Per Month

- 4-5 Week

- All India

Product Description

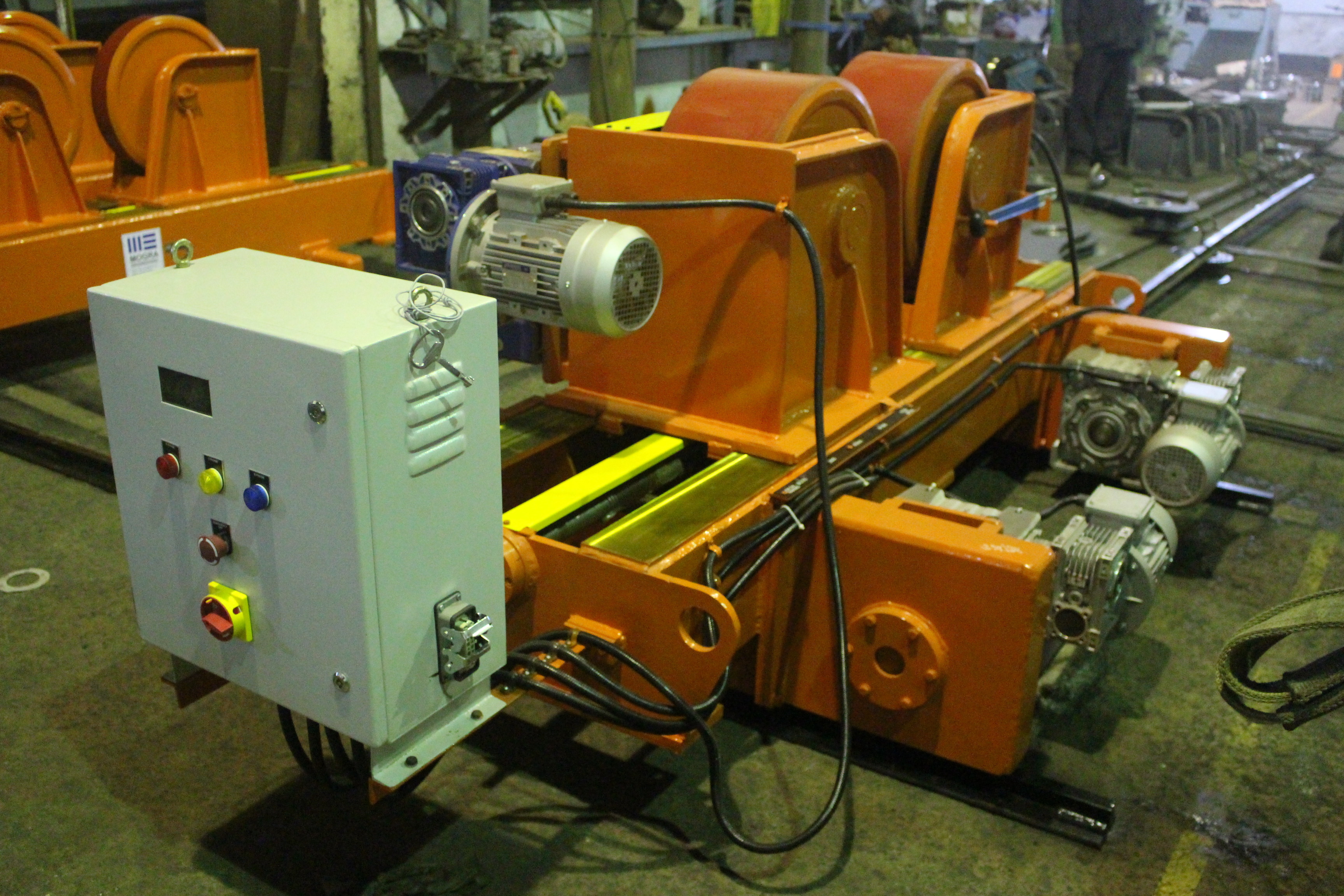

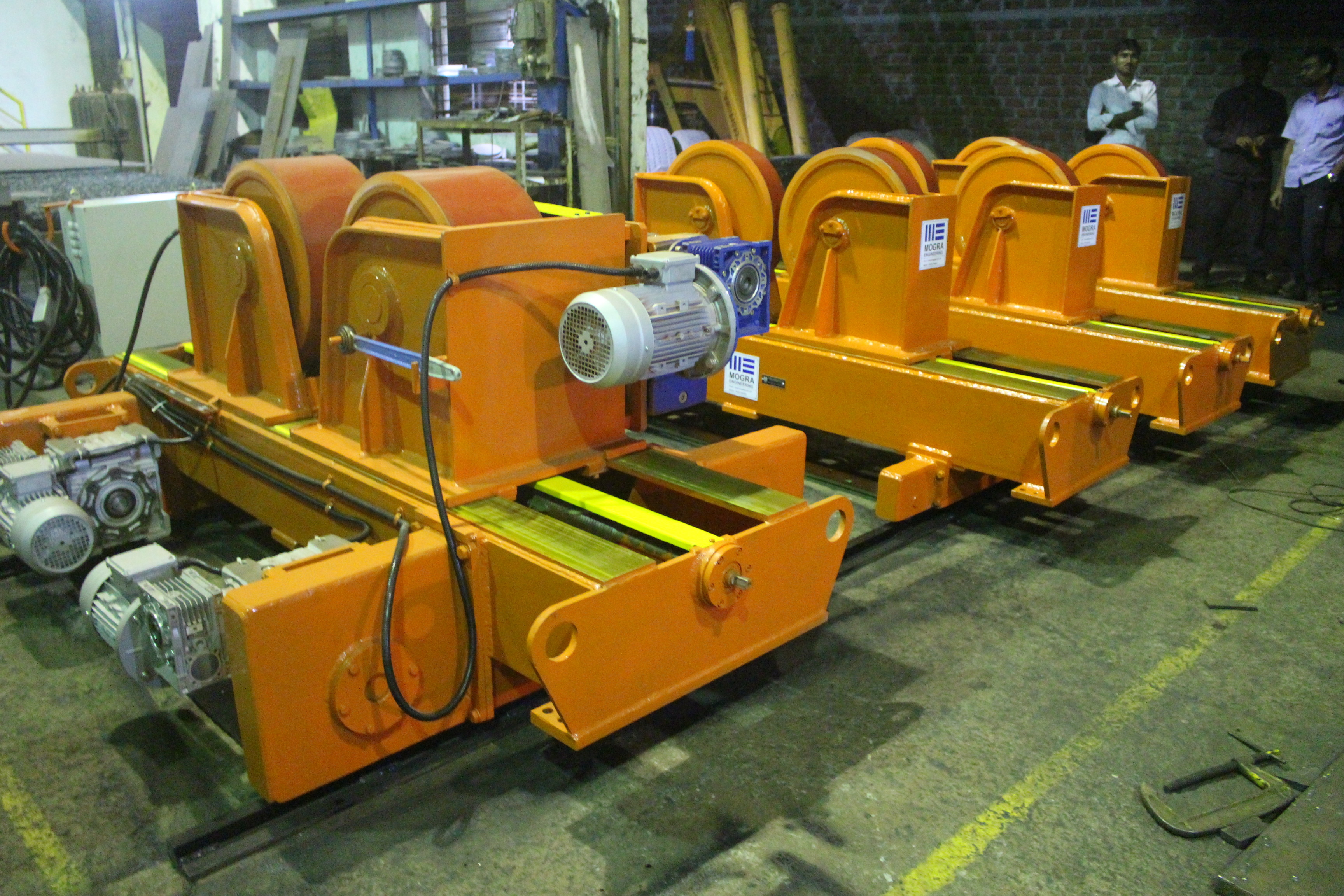

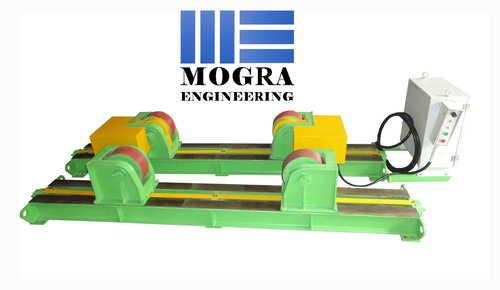

WELDING ROTATOR WITH POWER TROLLEY

- CAPACITY OF 60 MT

- CONSISTING OF 1 DRIVE UNIT WITH POWER TROLLEY

- AND 3 IDLER UNIT WITH MANUAL TROLLEY

- DRIVE ROTATING CAPACITY - 60 MT

- POWER TROLLEY CAPACITY- 60 MT

- IDLER LOAD BEARING CAPCITY - 10 MT EACH

1 SET CONSIST OF 1 DRIVE UNIT & 3 IDLER UNIT

Specification

| Roller Width | 100 to 250 mm |

| Color | Yellow |

| Voltage | 220-240 V |

| Diameter | 600 to 1200 mm |

| Frequency | 50 Hz |

| Capacity | 1 to 160 Ton |

| Warranty | 12 Month |

| Brand | Mogra |

Precision and Safety Combined

This welding rotator offers outstanding precision in rotating pipes and vessels during welding, supported by variable speeds and consistent power output. The robust polyurethane and steel rollers effectively minimize slippage, while the powder-coated mild steel structure ensures durability and corrosion resistance. An IP54 protection class safeguards components from dust and splashing water, providing a safe working environment.

Flexible Control and User-Friendly Operation

Designed for operator convenience, the rotator features both remote pendant and foot pedal control, enabling smooth and safe handling of heavy workpieces. The semi-automatic operation allows users to tailor the process for submerged arc, MIG, TIG, or manual welding, accommodating a range of industrial needs. Its floor-mounted design ensures stability and easy integration into various workshop setups.

FAQ's of Welding Rotator:

Q: How does the welding rotator accommodate different workpiece sizes?

A: The welding rotator can handle cylindrical workpieces with diameters ranging from 250 mm to 3,500 mm, making it suitable for pipes, tanks, vessels, and cylinders. The adjustable roller center distance of 1,000 mm and robust four-roller system ensure stable support for a variety of project requirements.Q: What is the process for controlling the welding rotator during operation?

A: Operators can control the rotator using a remote pendant or a foot pedal, both of which allow for precise adjustments to the rotation speed (100 - 1,000 mm/min). This flexibility makes it easy to match the rotator speed to different welding processes like MIG, TIG, submerged arc, or manual welding.Q: When should this welding rotator be used instead of manual turning?

A: This equipment is ideal when working with heavy or large cylindrical components where manual turning is impractical or unsafe, particularly for loads up to 10,000 kg. It enhances weld quality and consistency while minimizing operator fatigue and risk of workplace injury.Q: Where can the welding rotator be installed?

A: The floor-mounted design makes it suitable for installation in industrial workshops and fabrication facilities. Its robust construction and standardized dimensions (3500 x 1000 x 950 mm) allow easy placement in dedicated welding bays for pipe, tank, and vessel manufacturing.Q: What are the key benefits of using this welding rotator?

A: Key benefits include improved welding accuracy, reduced manual labor, enhanced safety, and consistent rotational speeds. The semi-automatic operation and variable controls optimize the welding process, boosting productivity and ensuring high-quality joints on a wide range of cylindrical components.Q: Which welding techniques are compatible with this equipment?

A: This rotator supports various welding methods such as submerged arc, MIG, TIG, and manual techniques, making it highly versatile for different fabrication and repair tasks in multiple industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email